Brand : AUTOFLEX

Last Update : 16/09/2559 14:25 Preview : 23,630

Corrugated Expansion Joint, Metal Bellows, Expansion Joint, Metal Joint, Stainless Steel Vacuum Pipe Bellows, Metal Bellow Expansion Joint for Vacuum : SS304, SS316

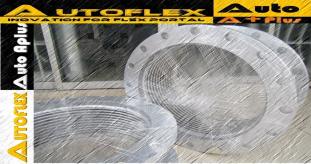

Flange Connection Flexible Metal Hose

Product Description : Flange Connection Flexible Metal Hose

Product Description :

Size Range : DN6 up to DN600

Wall Thickness : 0.15 Up To 0.8 mm

Material : SUS304, SUS316, SUS321

Standard : ASTM, DIN, JIS

Cross - Section Shape : Round

Usage : Protect Hose

Hose Type : Corrugated Metal Hoses And Helical Metal Hose

Connection Type : Flange

Brand : ALFAGOMMA

Last Update : 30/08/2559 10:25 Preview : 14,636

PETROLEUM SUCTION HOSE OR FUEL - OIL S&D T605 - 10 BAR OR 150 PSI BLACK

T605AA - 150 PSI Black Petroleum Suction Hose

Application: For suction and discharge applications in truck and tank car transfer of gasoline, oil and other petroleum-based products with up to 50% aromatic content.

Note: T605AA is not recommended for use on a reel.

WORKING PRESSURE : Constant Pressure 150 PSI

Construction :

-Tube: Black conductive NBR

-Reinforcement : High tensile textile cords and steel helix wires.

Cover : Black CR – abrasion, ozone and hydrocarbon resistant.

Temperature : -22 to 176 ºF ,-30 to 80 ºC

Brand : AUTOFLEX

Last Update : 10/09/2559 06:31 Preview : 19,299

UNION - 150 LBS SUS304,316L,GALVANIZED (ยูเนี่ยนต่อท่อประปาเหล็ก),CARBON STEEL SS400 TYPE.THEADED - SOCKET UNION

Production art:investment casting Material: SS316 SS304 SS400

Type:union conical ;union cone;union flat

Size: 1/8”~4”

Thread: BSP NPT

Standard: ISO4144;SP114;JIS

Pressure:ANSI Class 150lbs

Application:Water, Gas, Oil ect

Brand : MC SEAL

Last Update : 09/08/2559 06:51 Preview : 10,094

GLAND PACKING 4001 PTFE With Lubricate Dipped Braided Packing Product Details Model NO.: MK-4001 Standard: Standard Material: PTFE+ Silicone Oil Usage: Pump, Compressor, Valve Size Range: 4mm-50mm Product Description 1.Braided with Pure PTFE yarn and treated with high temperature-resistant silicone oil, minimizing shaft worn-out due to best self-lubrication. applicable for dynamic seal at high linear speed. 2. 100% White Expanded PTFE Packing is designed for use in valves, but can be used in other low speed services. 3. Fast and simple to install, with minimum maintenance requirements. Pure Teflon Packing can be adjusted very finely and reduced to extremely low levels. 4. High chemical resistance, very low coefficients of friction. 5. 100% White Expanded PTFE Packing is suitable for valves and pumps used in food processing, pharmaceuticals, paper mills, fiber plant, where high purity and corrosion resistance is required.

Brand : AUTOFLEX

Last Update : 19/09/2559 06:49 Preview : 21,390

FLEXIBLE HOSE SUS304, SUS321, SUS316 - FLANGE SUS304, SUS316, SUS400 10K, 150P, PN16 WITH BOTH END FIXED 2 SIDE

TUBE AND BRAID AVAILABLE : SUS304, SUS321, SUS316, BRAIDED MESH LAYER : SINGLE LAYER

Flexible Stainless Steel Hoses Seal

Flexible stainless steel hose (sleeves) sealed, are designed for transportation of liquid and gaseous media, for water, steam, condensate, gas and petroleum products, chemical products. Operate in extreme conditions, operating pressures and temperatures.

Spiral shaped convolution spiral advance profiled steel band with subsequent contact and seam welding. They have a diameter of 6 mm to 300 mm and lengths from 250 to 6000 mm. For the production of this type of hose used stainless strip thickness 0,15-0,40 mm.

High-quality steel airtight hose is not advisable to use in systems with a high level of vibration as the exploitation of metal hoses in such conditions leads to a resonant vibration of the corrugations or shells entirely.

Spiral represented by two species - rolled and corrugated variations. Corrugated metal oloruka made of seamless or longitudinally welded thin-walled tubes, which are formed by special mechanical or hydraulic devices and supplied with end fittings. They are used as low-cost flexible connecting elements as loading hoses and of movement, thermal expansion, vibration absorption.

Corrugated metal hose is completely waterproof, can be used to transfer liquids and gases under high pressure. In addition, the hose to the valve can be used in vacuum systems.

Addition weld metal hoses we supply hoses with flange with thread.

Due to the high reliability and durability to impacts flexible connection was in demand in the market pipelines and has been widely used in the automotive, aerospace, shipbuilding, metallurgy, petroleum, chemical, food, medical industry and many other industries.

Brand : AUTOFLEX

Last Update : 10/09/2559 06:32 Preview : 21,882

REDUCING HEX NIPPLE - 150 LBS STAINLESS STEEL SUS304 - SUS316 - CARBON STEEL SS400 : BSP,NPT

304 Stainless Steel has high corrosion resistance

Max Pressure: 150 Psi, Threaded with Hex

Working Temperature: -196°C to +220°C (321°F to 428°F)

NPT Threads (American Standard for Pipes)

Nipples are used to attach two female ended pipes

Brand : AUTOFLEX

Last Update : 08/11/2559 17:29 Preview : 24,469

FLEXIBLE PVC SPIRAL STEEL WIRE REINFORCED HOSE OR FLEXIBLE PVC SUPER SUN SPRING HOSE: SUPER SUN SPRING HOSE.

With hard steel wires put inside, this hose withstands to decompression, which is appropriate for vacuuming applications.Superior in transparency, this hose is appropriate for piping of operating oil

Brand : AUTOFLEX

Last Update : 30/11/2558 12:58 Preview : 11,129

Teflon PTFE Back - Up Rings have no Intended Sealing Function. Instead, as Their Name Indicates, They are Protective and Supporting Elements Made from Extrusion - Resistant Materials which Generally have a Rectangular Cross Section. They are Installed in a Groove Together with am Elastomeric Sealing Element Preferably with a Corresponding O - Ring in Static applications.Due to the Tight Fit of the Back - Up Ring in the Housing, They Prevent Extrusion of the Pressurized Elastomeric Sealing Element into the Sealing gap.